Context

In order to automatically regulate hydroelectric schemes, systems rely on level measurements at certain characteristic points of the reservoirs (control points), as well as on flows at the structures (dams and plants). Sufficiently accurate flow data are therefore essential for effective overall control of the hydroelectric chain.

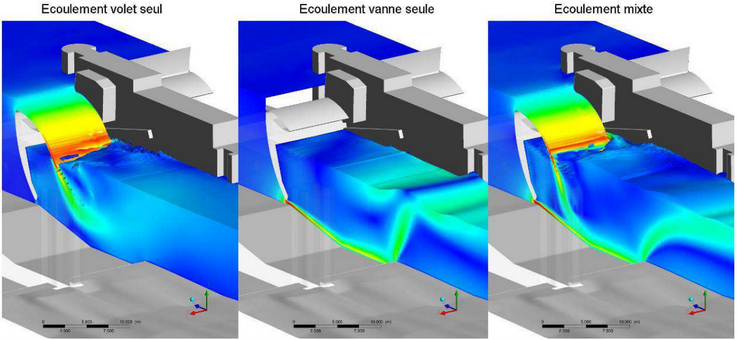

The dam studied here features two types of discharge device: flap gates, which allow water to flow over the dam, and bottom gates, which allow water to flow under the dam. The fundamental role of these elements is to control flooding by maintaining the dam’s elevation below its stability limit during these episodes. Their main function is therefore to ensure the safety of the structure. Their design incorporates safety coefficients to ensure that flood flows are largely evacuated. However, there are other reasons why we need to know the flow rate of these devices as accurately as possible:

- The first is legislation, which imposes an instream flow on natural watercourses to maintain fauna, flora and agricultural uses.

- The second is the economic stakes for the operator, since what is discharged by the spillways is not turbined, and therefore represents a loss of income.

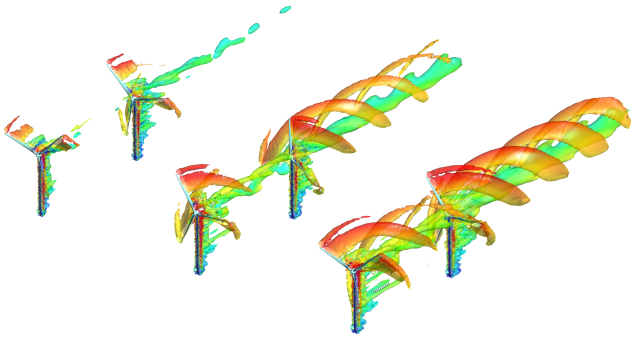

To achieve the best possible prediction, operators use physical models. However, these models are built at scales that do not always capture all phenomena.