Context

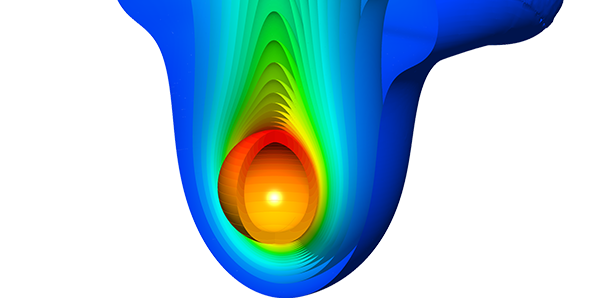

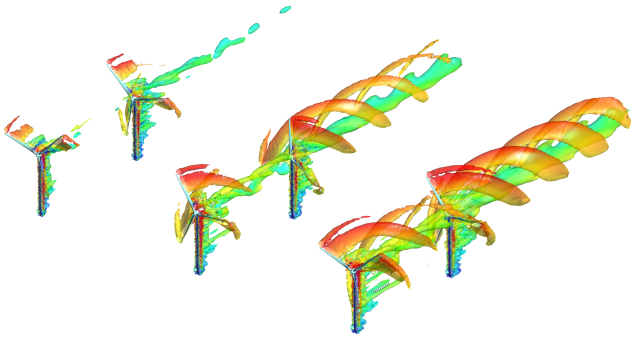

Sprays, aerosols and other atomizers have many industrial applications : from nasal cleansing sprays to car engine injectors, from paint spraying to insulating foams and fire protection. Their simulation is made complex by the multiplicity and finesse of the physical phenomena governing droplet cloud generation. OptiFluides carries out CFD simulations of sprays to help in the development of such devices.

Depending on the application, the characteristics of the aerosol cloud generated must meet certain requirements:

- In the case of nasal cleansing, for example, the aim is to ensure that the spray cleans the entire mucous membrane of the respiratory tract. Vaccines currently being developed also rely on sprays to deliver the active substance to specifically targeted areas. In this case, it is necessary to check that the active substance is actually delivered.

- Droplet size distribution will be an important parameter, particularly for engines, in order to promote the mixing of fuel and oxidizer, and thus achieve better combustion efficiency.

- The shape and angle of the spray cone will be essential for correctly dimensioning a sprinkler system for fire protection or paint applicators.