CFD modeling for projects of the energy and environment sector

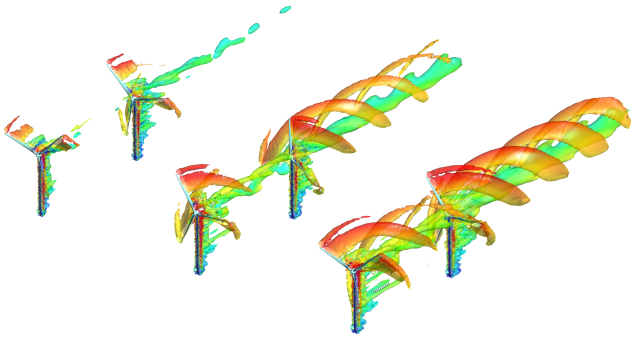

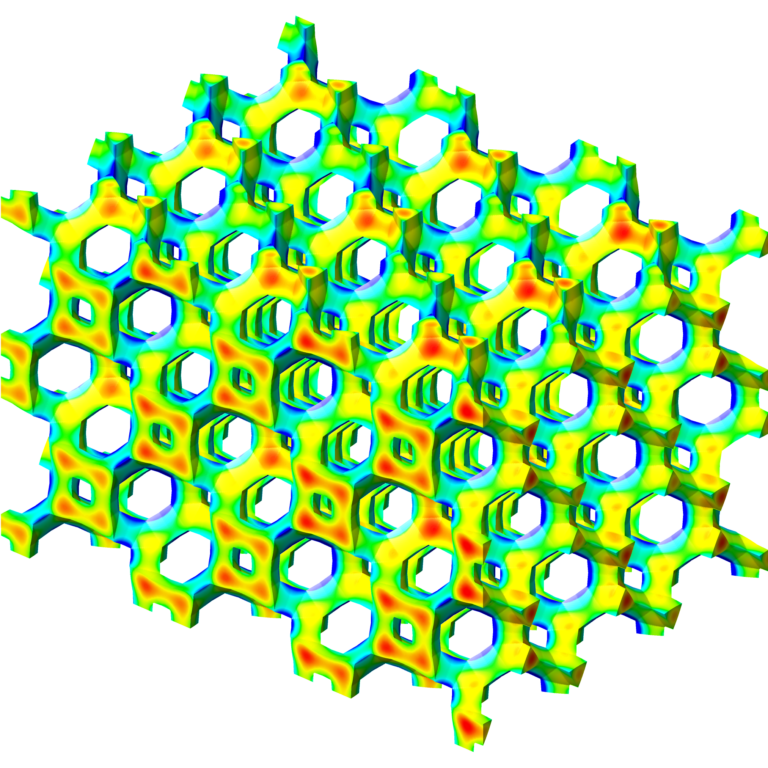

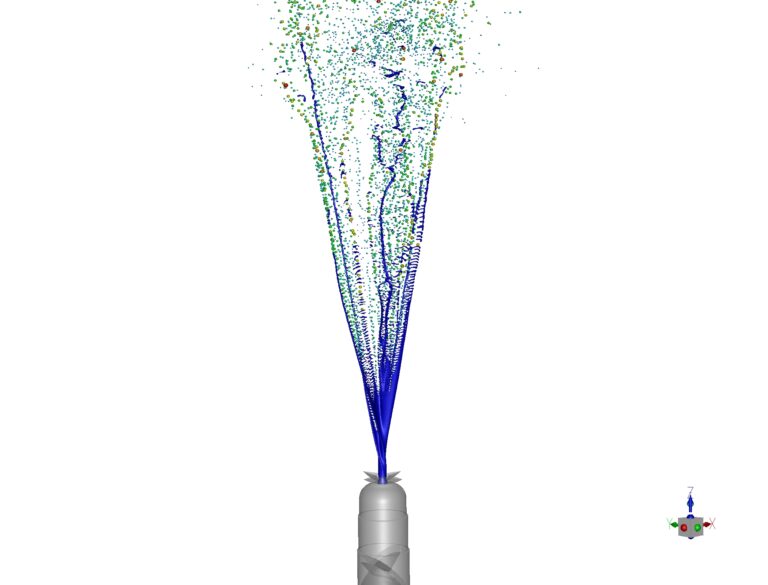

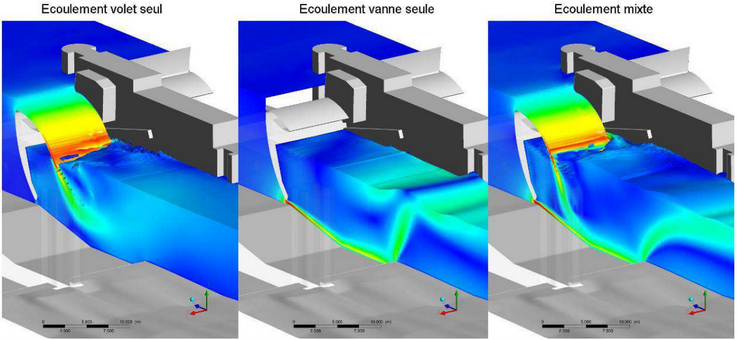

Fluids are omnipresent in energy production: as heat transfer fluids in industrial boilers for thermal or nuclear power plants, as a source of hydraulic energy converted into electricity by dams and tidal turbines, or even for electricity storage in fuel cells. It is therefore natural for CFD to find a place of choice within this ecosystem.

Similarly, environmental issues are a growing concern for manufacturers. Whether for eco-design, energy efficiency or technological risk assessment, but also for wastewater management or optimization of renewable energy production resources, numerous levers are available through Computational Fluid Dynamics.

OptiFluides has carried out numerous projects in this sector, developing cutting-edge skills and now boasts recognized expertise.

Here are a few examples of the main applications of CFD simulation in the energy and environment sector.